Pneumatic Konveyörler

PNEUMATI-CON® Dilute Phase Pneumatic

Conveying Systems

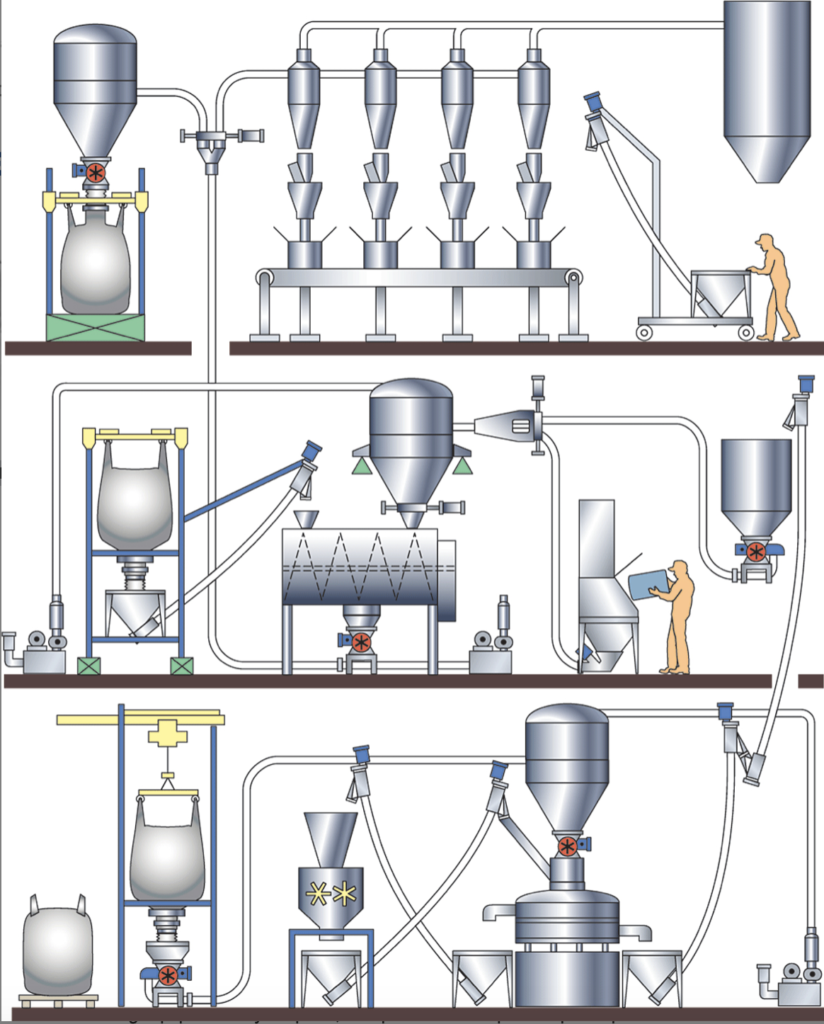

Flexicon’s PNEUMATI-CON dilute phase pneumatic conveying systems range from single-point “up-and-in” installations to cross-plant systems with multiple pick-up and discharge points and automated controls, satisfying an exceptionally wide range of bulk conveying applications. All are custom-engineered and fully integrated with other Flexicon equipment and systems, and your new or existing process.

PNEUMATI-CON dilute phase pneumatic conveying systems move bulk materials that are suspended in an air stream that is introduced by a positive pressure blower upstream of material intake points, or by a vacuum pump that removes air from the system downstream of material discharge points. Material is separated from the conveying air at the use point, then discharged on a batch basis via butterfly or slide gate valves, or continuously via rotary airlock valves.

Easy conveyor line routing

Since conveyor lines can be routed vertically and in any horizontal direction, over short or long distances, through small holes in walls or ceilings, Flexicon PNEUMATI-CON systems are easy to integrate into production environments in which process equipment and other obstacles often exist, while consuming minimal floor space.

Diversity of products handled by one conveyor

Powders having wide ranging bulk densities, as well as flakes, pellets, capsules, tablets and other friable materials, can be handled by a single Flexicon pneumatic conveyor, providing the flexibility needed to transport multiple ingredients.

Total evacuation

PNEUMATI-CON systems fully evacuate the vessel being discharged and the conveyor line itself, minimizing cross-contamination of multi-ingredient systems. Complete transfer of material also ensures that individual and consolidated batch ingredients reach their destinations accurately by weight, maximizing quality while minimizing waste.

Wide capacity range

With a PNEUMATI-CON conveyor, capacity can range from several pounds to tens of tons per hour, feeding any destination from small packaging lines to silos and railcars. Moreover, excessive fluctuations in the feed rate — resulting in overloading or underloading — will not damage the system.

Enclosed system prevents contamination

Totally enclosed and dust-free, a PNEUMATI-CON conveying system prevents contamination of the product and plant environment, allowing safe transfer of contamination-sensitive materials including dusty and hazardous products.

High reliability and ease of maintenance

Flexicon PNEUMATI-CON systems feature easy-to-maintain filter receivers with access doors and inspection ports, as well as rotary airlock valves with optional rotor support bars for easy access, cleaning and inspection.

Mobile and custom configurations

Self-contained Flexicon PNEUMATI-CON conveying systems complete with feed hopper and/or pick-up wand, blower unit, filter receiver and control package, are available pre-engineered and configured on caster-mounted frames for in-plant mobility.

Designed, constructed and finished to industrial and sanitary standards

PNEUMATI-CON conveying systems are available in carbon steel with durable industrial finishes, or stainless steel finished to standards required for industrial, food, dairy and pharmaceutical applications. Available upgrades include quick-access and quick-disconnect fitments.

System Types

Positive pressure systems

Positive pressure dilute phase pneumatic conveying systems are typically employed to convey bulk materials from a single source to one or multiple destinations, over longer distances and with greater capacity than possible using vacuum systems.

These systems utilize a positive displacement blower with single or multiple downstream material entry points, each of which meters product into conveying lines by means of a rotary airlock valve that maintains the pressure differential between the ambient atmosphere and that of the conveying line. Material and air blown through the line exit at single or multiple use points where they are separated by means of a filter receiver or cyclone separator, or fed directly into process vessels that are vented to downstream dust collection devices.

Pressure systems offer higher efficiency than vacuum systems, can convey over longer distances, and can blow directly into process and storage vessels without the use of a rotary airlock valve.

Vacuum systems

Vacuum dilute phase pneumatic conveying systems are generally employed for transporting material from multiple sources such as storage vessels, process equipment, trucks and railcars, to individual or multiple destinations. Unlike positive pressure systems, vacuum systems allow easy pick-up of materials from open containers using wands, and do not impart heat to the material. Since vacuum systems offer superior leak containment, they are often specified on the basis of cleanliness, particularly when handling hazardous materials.

Negative pressure is created by a positive displacement vacuum pump located at the downstream end of the system. Material typically enters the system via upstream rotary airlock valves, hand-held pick-up wands, and non-flow-through/flood-feed pick-up adapters, and exits the system through filter receivers or cyclone separators that separate the material from the conveying air directly above process equipment, inlet hoppers, storage vessels or other discharge points.

In addition, vacuum conveying is suited to direct feeding of blenders, reactors and other enclosed process vessels that are put under vacuum by a line terminating at a downstream bag house or other dust collection device, eliminating the need for individual filter receivers or cyclone separators above each discharge point.

A complete range of pneumatic system components

Flexicon provides any and all components necessary to configure your PNEUMATI-CON system including:

- Flex-tube diverters, wye-diverters, plug diverters and other line diverter configurations

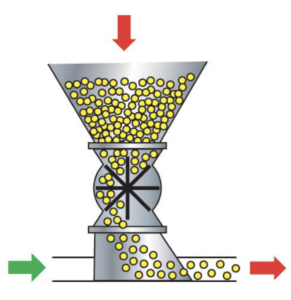

- Rotary airlock valves in all popular designs and sizes

- Filter receivers for low- to high-capacity applications

- Cyclone separators for low- to high-capacity applications

- Gain-in-weight and loss-of-weight batching systems

- Dust collectors and bin vents

- Controls and electrical equipment

- Hand-held pick-up wands

- Silos, day bins and other storage vessels

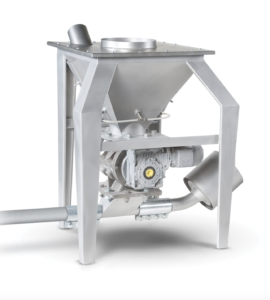

Flexicon’s Sanitary Bag Dump Station collects dust created during manual dumping of bulk materials from bags, boxes, drums and other containers, and allows rapid, tool-free wash down. Optional rocker arms support the hood assembly above the hopper rim, eliminating the need for operators to lift and remove the hood during cleaning and inspection. Shown with quick-clean rotary airlock.

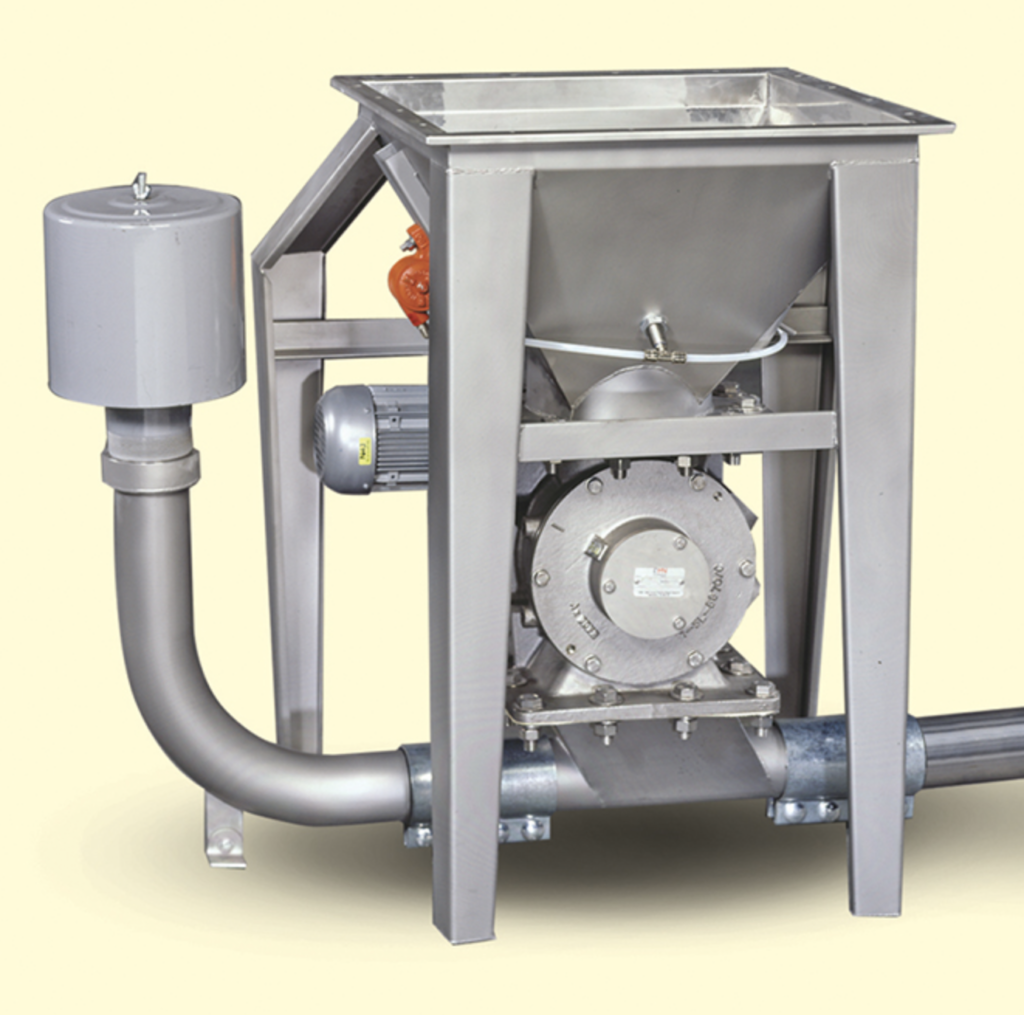

Sanitary stainless steel inlet hopper is gravity-fed from upstream process equipment or storage vessels. A sanitary stainless steel rotary airlock valve at the hopper discharge is equipped with integral support rails that allow the rotor assembly to separate from the valve body for sanitizing of all material contact surfaces, and to close securely in seconds — tool-free.

Flexicon storage vessels in carbon steel with durable coatings (shown) and in stainless steel are available equipped with flow promotion devices and rotary airlock valves for consistent metering of bulk material into positive pressure or vacuum pneumatic conveyor lines. With optional load cells and programmable controls, vessels can serve as loss-of-weight batching systems.

PNEUMATI-CON filter receivers incorporate numerous design and construction innovations offering unsurpassed separation efficiency across all capacity ranges. Low-capacity units are commonly positioned above packaging lines or smaller process equipment, while medium capacity units are utilized above storage vessels and process equipment such as blenders and bulk bag fillers.

This Silo Vent is essentially the upper section of a filter receiver that can be mounted atop an existing silo or other large vessel, into which material can be conveyed.

This modular vacuum receiver features a rugged clamp-together design that facilitates rapid disassembly for filter maintenance and cleaning. Whereas conventional filter receivers employ multiple smaller elements, it employs a single, large diameter filter cartridge, and offers an ideal solution for low-throughput-rate, short-distance pneumatic conveying applications.

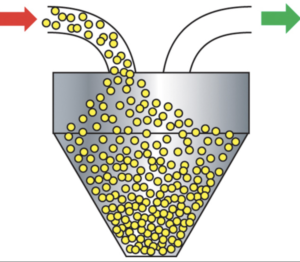

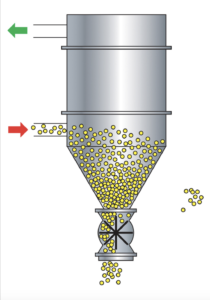

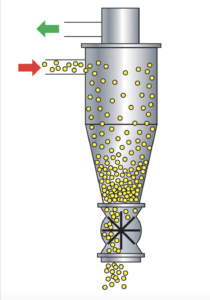

Unlike filter receivers, cyclone separators require no filters to separate solid particles from the gas stream, instead relying on cyclonic action alone. An air stream containing material enters the separator at a tangential angle and is spun rapidly, creating a circular flow that imparts centrifugal force to the particles which strike the wall of the cyclone and fall through a bottom outlet, into a process vessel.

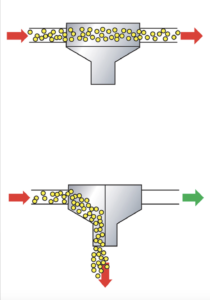

PNEUMATI-CON® Fill/pass valves allow material to be discharged at single or multiple points along a common vacuum or positive-pressure dilute-phase conveying line. The valves can be actuated to divert material from the conveying line manually from a control panel, on timed cycles or — when equipped with a gain-in-weight hopper (shown) — by weight of material discharged.

Material intake methods

Pressure and vacuum conveying systems commonly utilize rotary airlock valves to introduce material to the air stream. Hand-held wands and non-flow-through (flood-feed) pick-up adapters can be utilized with vacuum systems.

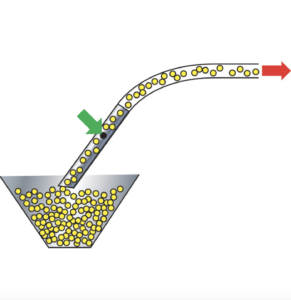

Rotary Airlock Valves with Flow-Through Pick-Up Adapters

(Pressure and vacuum systems)

Rotary airlock valves with flowthrough pick-up adapters can be utilized in pressure and vacuum systems for both controlled metering of material into the conveying system, and maintaining the pressure differential between the conveying system and ambient atmosphere.

Wands

(Vacuum systems)

Hand-held pick-up wands plumbed to vacuum conveyor lines with flexible hose are used to vacuum material from Gaylords, drums, paper bags, barrels or other containers.

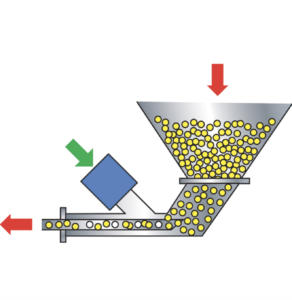

Non-Flow-Through (Flood-Feed) Pick-Up Adapters

(Vacuum systems)

Material can be introduced into vacuum conveyor lines via non-flow-through (flood-feed) pick-up adapters, which are typically used at pick-up points where lower volumes of material are fed manually.

Material pick-up points, clockwise from top left, include hand-held pick-up wand, rotary airlock with flow-through adapter, non-flow-through pick-up adapter, and rotary airlock with flow-through pick-up adapter.

Material discharge methods

Material typically exits pressure and vacuum pneumatic conveyors via filter receivers or cyclone separators, or discharges directly into process or storage vessels. Positive pressure systems can additionally employ fill/pass valves to discharge material from the system at one use point, or redirect the material to another use point.

Directly into Process Vessels

(Pressure and vacuum systems)

Both pressure and vacuum systems can feed material directly into blenders, reactors and other enclosed process vessels that are vented to a downstream bag house or other dust collection device, eliminating the need for individual filter receivers.

Filter Receivers

(Pressure and vacuum systems)

Flexicon filter receivers separate solids from the air stream using filter media and gravity, and are generally specified when materials contain smaller particles that are prone to dusting and/or when dust containment is a primary requirement. They are normally located above material use points, and employ reverse-pulse jet filter cleaning to dislodge accumulated dust from filter surfaces, allowing continuous and efficient separation of material from the air stream.

Cyclone Separators

(Pressure and vacuum systems)

Cyclones separate solids from the conveyor air stream using centrifugal force and gravity, and are typically specified when materials are comprised of larger particle sizes that are not prone to dusting. Although filters are uncommon, they can be incorporated as a secondary means of capturing airborne solids.

Fill/Pass Valves

(Pressure and vacuum systems)

Fill/pass valves are commonly used to discharge material directly into individual or multiple process vessels and/or to deliver it to several destinations along a common conveying line. Downstream of the last fill/pass valve, the conveying line is normally routed to the original material source point or into a dust collection device.