Bulk Bag Discharger and Fillers

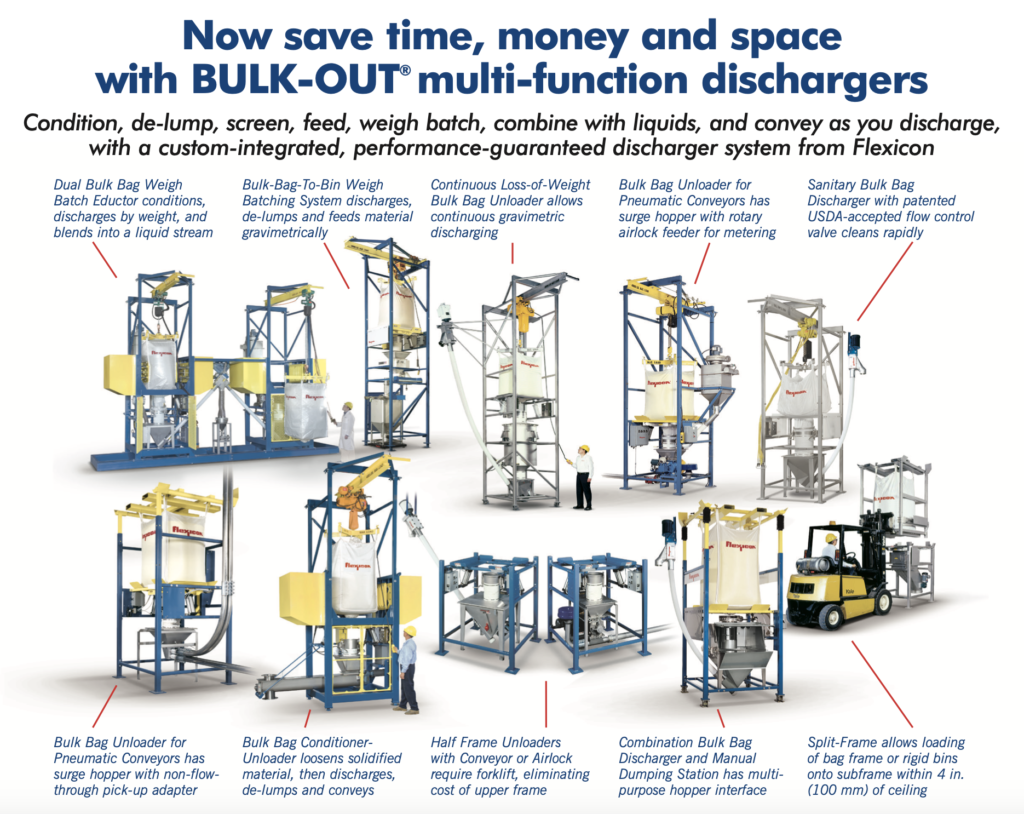

Condition, de-lump, screen, feed, weigh batch, combine with liquids, and convey as you discharge, with a custom-integrated, performance-guaranteed discharger system from Flexicon

Bulk Bag Discharges

Flexicon BULK-OUT® Bulk Bag Dischargers (also known as FIBC, Big Bag and Jumbo Bag unloaders) are offered in numerous frame configurations. The two most popular are BFF Series dischargers with bag lifting frame for forklift loading and unloading of bulk bags, and BFC Series dischargers with cantilevered I-beam, electric hoist and trolley for loading and unloading of bulk bags without the use of a forklift.

Other bulk bag unloader configurations include split frames for forklift loading of bags in low headroom areas, half frames for suspending bags during discharge using a forklift, continuous loss-of-weight dischargers for uninterrupted feeding directly from bulk bags, and other designs satisfying highly specialized requirements.

All BULK-OUT® Bulk Bag Dischargers are offered with a broad range of innovative accessories (many patented), delivering an unprecedented level of efficiency, cleanliness and economy. A range of integral flow promotion devices is available, as are dedicated bulk bag conditioners that loosen bulk solid materials that have solidified during storage and shipment, enabling bulk bag unloaders to discharge the material through bag spouts.

Bulk Bag Filling

Flexicon bulk bag fillers (also known as FIBC, Big Bag and Jumbo Bag Fillers) range from basic stand-alone units to sophisticated systems to match the budget and capacity requirements of each customer’s application. Each of these configurations delivers optimum performance across specific capacity ranges with maximum cost-effectiveness.

Flexicon’s latest bulk bag filling innovation is the patent-pending SWING-DOWN®filler. Designed for medium- to high-capacity applications, this revolutionary design brings the fill head to the operator at floor level for faster, safer and easier bag connections.

REAR-POST fillers are intended for medium- to high-capacity applications requiring pass-through conveyors and/or powered fill head height adjustment.

Flexicon’s patented TWIN-CENTERPOSTTM fillers*, satisfy low- to medium-capacity filling requirements and/or sanitary applications where frequent wash-down or compliance with USDA Dairy standards is required.

Lighter-duty versions of TWIN-CENTERPOSTTM fillers, BASIC FILLERS reduce cost, yet offer an inflatable bag spout seal and feed chute dust vent as standard, and a limited list of performance options.

Each of these designs satisfies a distinct range of bulk bag filling applications, and is available with performance enhancements to meet your individual requirements with extreme cost effectiveness. From basic, low-cost fillers to automated, high-capacity systems and everything in between, Flexicon offers precisely what you need for bulk bag filling success.

Bulk Bag Conditioners

Flexicon BLOCK-BUSTER® Hydraulic Bulk Bag Conditioners (also known as FIBC, Big Bag and Jumbo Bag Massagers) loosen bulk solid materials that have solidified during storage and shipment, enabling bulk bag unloaders to discharge the material through bag spouts. These conditioners are recommended for bulk bags containing hygroscopic chemicals, certain types of spice blends, heat-sensitive products, and other materials prone to solidifying to the point at which pneumatically-actuated flow promotion accessories integral to bulk bag dischargers are inefficient or completely ineffective.

BLOCK-BUSTER® Hydraulic Bulk Bag Conditioners are available integrated into bulk bag unloading frames, or as self-standing units.

Both configurations utilize two hydraulic rams with specially contoured end plates to press opposing sides of bulk bags.