Flexible Screw Conveyors

Free-flowing and non-free-flowing materials and blends

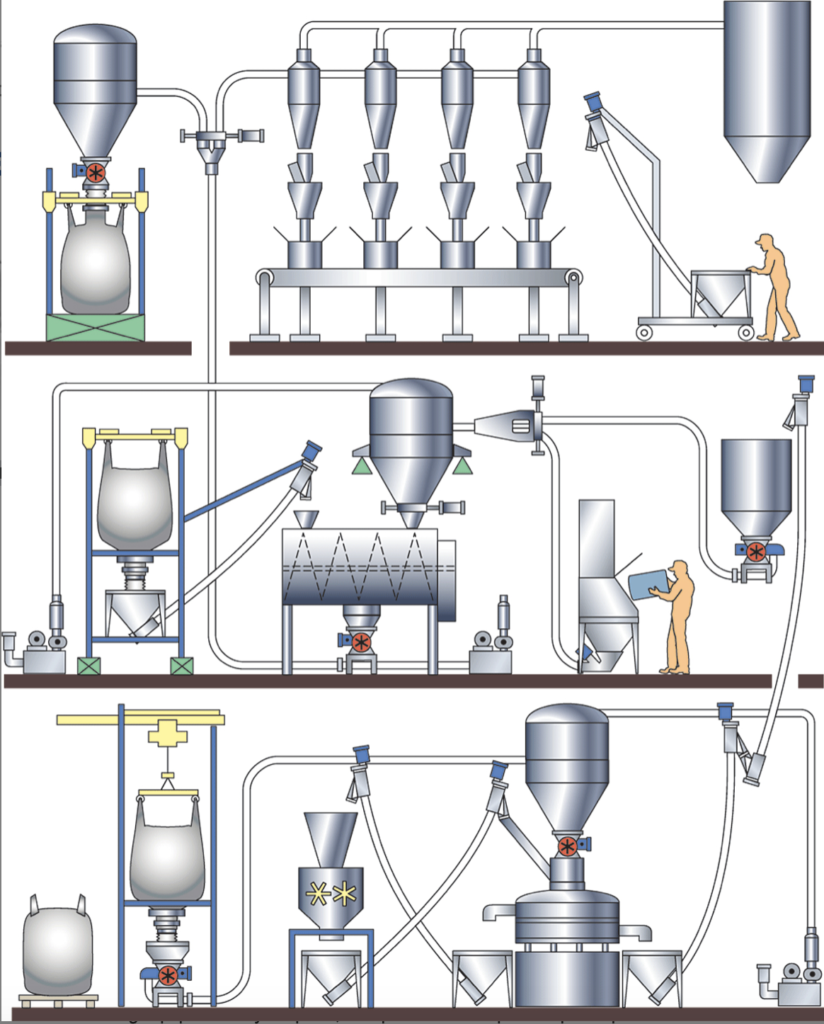

Flexicon flexible screw conveyors (also known as helix conveyors, screw conveyors, spiral conveyors and auger conveyors) offer efficiency and versatility, conveying bulk materials ranging from large pellets to sub-micron powders—both free-flowing and non-free-flowing—with no separation of blended products.

Mobile and custom configurations

All Flexicon flexible screw conveyors are available on caster-mounted frames with conveyor support masts for in-plant mobility, reducing the need for multiple stationary units.

Both mobile and stationary units are readily customized using interchangeable screws, conveyor tubes, drive motors, hoppers, flow-promotion devices, sensors, controllers, and other components to satisfy the most diverse and demanding end-use requirements.

Principle of operation

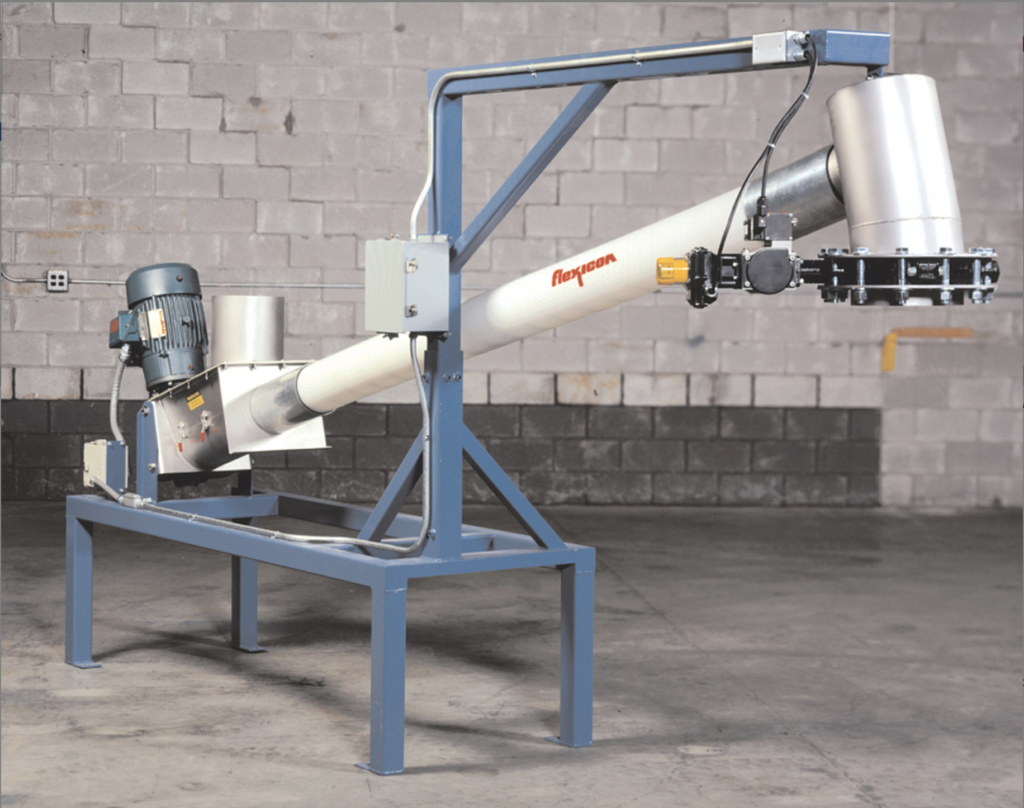

A Flexicon flexible screw conveyor (also known as helix conveyor, screw conveyor, spiral conveyor and auger conveyor) consists of a spring steel or stainless steel flexible screw that is enclosed in a flexible or rigid plastic tube, or a rigid steel tube, and driven by an electric motor normally located at the discharge end of the conveyor. This simple design delivers efficient performance and high reliability while reducing maintenance and cost. When properly engineered according to the specific characteristics of the material being conveyed and the process into which it will be integrated, a flexible screw conveyor can outperform rigid screw conveyors, bucket elevators, drag chain conveyors, aero mechanical conveyors and other equipment intended to transport powder and bulk solid materials.

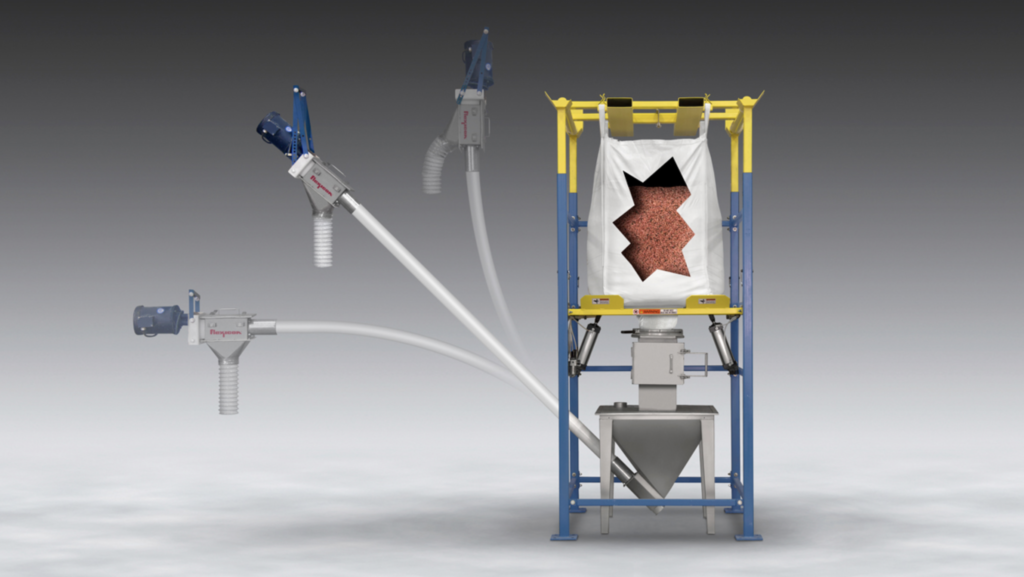

The intake end of a flexible screw conveyor tube is typically equipped with a charging adapter, a U-shaped trough that connects to the outlet of a hopper or directly to the outlet of process equipment such as a bulk bag discharger, bag dump station, grinder, crusher, screener, blender, reactor or storage vessel of any kind.

The flexible screw passes through the charging adapter trough, exposing a section of the screw to material flowing into the trough from above. When rotating, the exposed section of screw feeds material into the outer tube, where it is then propelled through the tube by the enclosed portion of the screw.

A phenomenon resulting from the loose fit of a rotating flexible screw within a tube filled with bulk material, is that the screw automatically self-centers within the tube, providing clearance between the screw and tube wall. This affords sufficient space for particles to flow without damage, depending on the fragility and size of particles being conveyed.

A removable clean-out cap covers the intake end of the conveyor tube, permitting rapid emptying and flushing of the tube, as well as disassembly and wash-down of components.

Because the intake end of the screw requires no bearing, and since the discharge end is coupled to the drive motor above and/or beyond the point at which material exits the discharge spout, material does not come in contact with seals or bearings. The flexible screw is therefore the only moving part contacting material.

Flexible screw pioneers

Perhaps no other manufacturer has advanced the application of the flexible screw conveyor as far and as fast as Flexicon—the first to introduce 4 1/2 in. (115mm), 6 in. (150mm), and 8 in. (200mm) diameter screw/tube combinations that elevated the capacity of this category of conveyor more than 10-fold in an 8-year period. After more than 22,000 installations worldwide involving a gamut of bulk materials, Flexicon has amassed a wealth of performance data on flexible screws—many of which have been engineered, machined and formed to Flexicon specifications. To you, it means that Flexicon has most likely solved your problem in the most efficient and cost-effective manner possible—or can do so as a matter of routine.

Enclosed tube prevents contamination

A Flexicon flexible screw conveyor (also known as helix conveyor, screw conveyor, spiral conveyor and auger conveyor) is totally enclosed, dust-free, and mess-free, preventing contamination of your bulk products and plant environment, while preserving the moisture and temperature levels of materials being conveyed.

Compare the smooth interior surfaces of a Flexicon flexible screw conveyor with potential contamination sources found in other conveyors, and you may specify the Flexicon flexible screw conveyor on the basis of product purity alone.

Fast, thorough cleaning

A Flexicon flexible screw conveyor has no internal cracks, crevices or bearings that can trap particles or prevent thorough cleaning. Simply remove the clean-out cap and reverse rotation to evacuate any residual material prior to flushing with air, water, steam, or cleaning solution. The screw and tube can be removed quickly for easy and thorough cleaning.

Design, construction and finishes satisfy cleanliness standards

Flexicon conveyors, as well as most other Flexicon equipment, are available in carbon steel with a variety of durable industrial finishes, or stainless steel finished to industrial, food, dairy, or pharmaceutical standards, including designed and constructed for 3-A compliance.